Ad

Supercapacitors from paddy?

4,187 views

Follow Us:

4,187 views

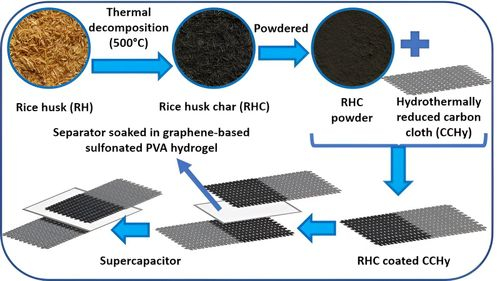

Through their work with organic waste, especially kitchen waste, the researchers are fostering a new 'Farm-Energy Synergy' to produce usable activated carbon, a key ingredient in making supercapacitors. Supercapacitors made from activated carbon produced from paddy waste offer numerous benefits to consumers in the electronics, energy, and agricultural industries and can contribute to self-sufficiency in the supercapacitors field.

Boosting self-reliance in supercapacitors and energy storage technology will also enhance IP generation and employment opportunities within the country. Currently, India generates around 760 lakh metric tons of paddy waste per year, and farmers often resort to burning straw as a low-cost and efficient alternative to tailing it into the soil, resulting in significant pollution and ecological issues. Burning also reduces the potential use of biomass, resulting in an estimated loss of approximately Rs 92,600 crore for India associated with this method of farm waste management.

Making Environmental Friendly Supercapacitors

The conversion of bio-waste into activated carbon has been successfully demonstrated by IIT Madras researchers, who have used vegetable waste to create supercapacitor electrode materials. They now plan to adapt this technology to convert paddy waste into activated carbon, with the goal of exploring scales of production. The project is being led by Dr Tiju Thomas, Associate Professor at the Department of Metallurgical and Materials, IIT Madras. The institute is seeking CSR Partners to support the project's scaling up and benefits to the country.

Dr Thomas emphasised that the proposed process is a well-defined solution, allowing for the conversion of paddy waste into commercial standard carbon material. The activated carbon can then be used to fabricate supercapacitors that comply with market standards, which can be implemented as a suitable supercapacitor-based hybrid energy storage device. The benefits of activated carbon extend beyond the energy sector, with applications in water treatment, pharmaceuticals, and biochar production. The devices produced by IIT Madras are useful not only for the energy sector but also for the mobility sector, with potential use in electric vehicles.

Latest News

Reviews & Guides

View All

Nothing Phone 3a Community Edition First Impressions: A Fresh Take on Budget Smartphones

Realme P4x 5G Review: Budget-Friendly Beast with Epic Battery Life

Sony BRAVIA 7 Mini LED K-65XR70 vs. Haier Mini LED H65M95EUX

Samsung QN90F (65QN90FAU) Review: The King of Bright-Room Viewing

Why doesn’t Apple reveal the iPhone battery in advertisements?

Top 10 camera lenses you should Own in 2025

Donald Trump Watch Collection: Timeless Luxury on the Wrist

Best Smartphones Under 30,000 in 2025